Pipeline Welding Inspection: Expert Services for High-Quality Welds

Pipeline Welding Inspection: Expert Services for High-Quality Welds

Blog Article

Recognizing the Fundamentals of Pipeline Welding Inspection: Critical Variables for Reviewing Weld Top Quality and Fighting Failures

In the world of pipe welding inspection, the stakes are undeniably high, necessitating an extensive understanding of essential concepts to guarantee weld high quality and reduce failing threats. Various essential elements come right into play, consisting of the selection of ideal products, the application of advanced evaluation strategies, and the acknowledgment of prevalent welding problems.

Value of Weld Top Quality

The honesty of a pipeline is basically dependent on the top quality of its welds, making weld quality a vital consider ensuring safe and efficient procedure. A pipe weld works as a joint factor where products are signed up with, and any type of shortages in this location can cause substantial structural weak points. Poor bonded top quality can result in leaks, tears, and catastrophic failings, posing severe safety and security threats and ecological dangers.

Several elements contribute to the high quality of a weld, including the option of welding process, the skills of the welder, and the conditions under which the welding is carried out - Pipeline Welding Inspection. Inadequate preparation, improper warmth input, and contamination can endanger weld honesty, causing problems such as porosity, insufficient blend, or fractures. As a result, strict quality assurance measures have to be applied throughout the welding procedure to reduce these dangers

Furthermore, the long-term efficiency of a pipeline is heavily affected by the toughness of its welds. Top notch welds not only boost the general stamina of the pipeline yet likewise extend its solution life, decreasing the need for pricey repair work and downtime. Hence, making certain premium weld high quality is critical in pipe design and upkeep methods.

Key Examination Methods

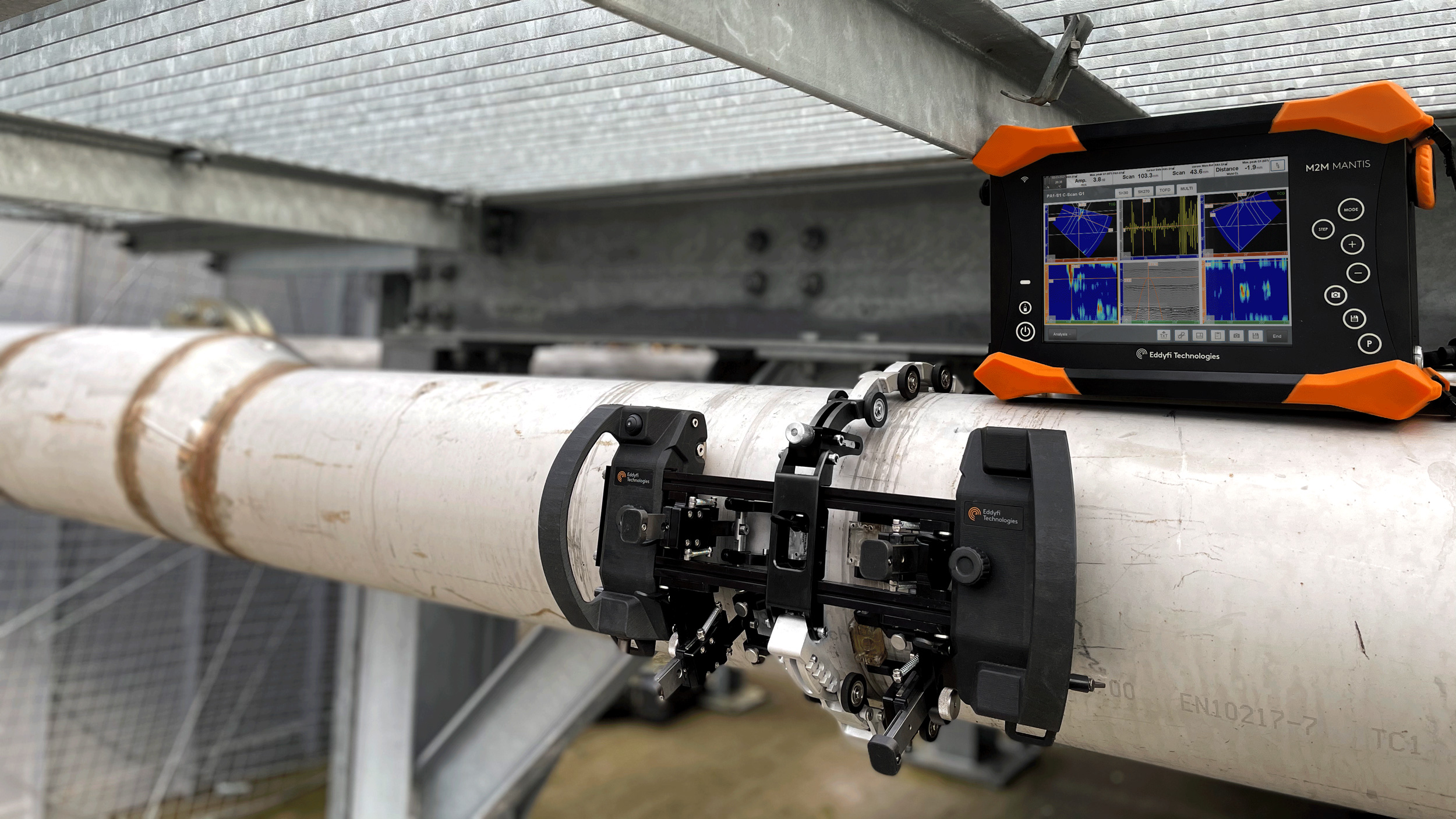

Making certain weld top quality requires the implementation of efficient examination methods to recognize prospective imperfections before they result in failings. Pipeline Welding Inspection. Among one of the most widely utilized approaches are visual examination, radiographic screening (RT), ultrasonic testing (UT), and magnetic bit screening (MT) Each method is and offers a distinct function picked based upon the particular demands of the pipe job

Aesthetic examination is the first line of defense, permitting assessors to evaluate surface problems, placement, and overall craftsmanship. It is a affordable and quick technique that can disclose noticeable defects. Radiographic testing offers a thorough view of internal weld integrity by utilizing X-rays or gamma rays to find subsurface imperfections. This technique is particularly effective for identifying fractures, spaces, and additions.

Ultrasonic testing employs high-frequency acoustic waves to review the thickness and integrity of welds, making it ideal for identifying inner stoppages. Magnetic fragment testing is a reputable method for identifying surface area and near-surface problems on ferromagnetic materials by using electromagnetic fields and fine ferrous fragments. By making use of these crucial evaluation techniques, pipe welding examiners can ensure the highest possible high quality standards are kept, eventually leading to more secure and much more reliable pipe systems.

Common Welding Issues

Among the most widespread flaws are porosity, which takes place when gas allures in the weld metal, producing gaps that weaken the joint. One more substantial issue is lack of blend, where the weld steel does not properly bond with the base product, compromising the joint's stamina.

Fractures are likewise a critical issue, materializing in numerous forms such as hot fractures, cool splits, and root fractures. Each kind postures unique challenges and needs certain examination visit this site strategies for detection. Undercut is one more flaw that can minimize the weld's cross-sectional location, leading to tension focus factors, while slag incorporation occurs when non-metallic material becomes caught in the weld pool, detrimentally affecting the mechanical homes of the weld.

Furthermore, incorrect bead shape can lead to irregular stress circulation. Identifying these common issues is essential for inspectors and welders alike, as early discovery and improvement are vital to ensuring the longevity and integrity of pipe systems.

Materials and Their Effect

Selecting the suitable products for pipe welding substantially affects the overall performance and integrity of the bonded joints. The choice of base metals, filler materials, and layers plays an important duty in determining the stamina, rust resistance, and longevity of the welds. As an example, carbon steel is frequently used for its balance of stamina and price, but it may be prone to corrosion in particular environments, requiring making use of corrosion-resistant alloys or protective coatings.

Moreover, dissimilar metal welding calls for mindful factor to consider of thermal development properties and potential galvanic deterioration. The compatibility of products can substantially influence the microstructure of the weld, causing variations in mechanical homes. As an example, stainless steel offers superb deterioration resistance however may require details filler products to make sure a sound weld joint.

Furthermore, the influence of temperature and environmental problems on product choice can not be underestimated. High-strength steels might shed ductility at elevated temperature dig this levels, while low-temperature applications could need materials with enhanced sturdiness. Inevitably, comprehending the implications of product selections is crucial for attaining ideal weld high quality and preventing failings in pipeline systems.

Regulative Requirements and Compliance

Regulatory standards and compliance play a critical function in pipeline welding, establishing the framework within which effective and risk-free practices are kept. These criteria are created by different organizations, including the American Society of Mechanical Designers (ASME), the American Welding Culture (AWS), and the Pipe and Hazardous Materials Safety And Security Administration (PHMSA) Sticking to these laws makes certain that welding treatments meet the required top quality and safety and security criteria.

Compliance with governing criteria is necessary not only for ensuring the honesty of the welds however also for protecting the setting and public security. Examiners are tasked with validating that welding operations abide by these criteria with rigorous exams of both the procedures and the final welds. This involves assessing welder certifications, welding procedures, and the products used.

Failing to conform with established laws can cause considerable consequences, consisting of costly fixings, legal responsibilities, and disastrous failures. Therefore, companies must incorporate compliance right into their operational techniques, fostering a society of safety and high quality. Normal training and audits are vital parts in maintaining adherence to these governing standards, making sure that all personnel are knowledgeable and equipped to maintain the highest degree of click reference pipe welding top quality.

Final Thought

Finally, a detailed understanding of pipe welding evaluation is crucial for making certain weld quality and stopping failings. By employing crucial examination methods and recognizing typical welding flaws, assessors can properly assess the integrity of welds. Consideration of material selection and adherence to regulatory standards even more improve the dependability and security of pipeline systems. Eventually, these methods contribute to the prevention of leaks and catastrophic failures, underscoring the critical importance of rigorous inspection procedures in pipe building and construction and upkeep.

In the world of pipe welding evaluation, the stakes are undeniably high, demanding a detailed understanding of essential principles to make sure weld top quality and reduce failure dangers (Pipeline Welding Inspection).The honesty of a pipeline is basically reliant on the top quality of its welds, making weld high quality a vital variable in guaranteeing safe and efficient operation.Several variables contribute to the top quality of a weld, including the selection of welding process, the abilities of the welder, and the conditions under which the welding is executed. Undercut is another issue that can decrease the weld's cross-sectional location, leading to stress focus factors, while slag addition takes place when non-metallic material ends up being trapped in the weld pool, detrimentally affecting the mechanical residential or commercial properties of the weld

In verdict, a comprehensive understanding of pipe welding inspection is important for making certain weld quality and stopping failings.

Report this page